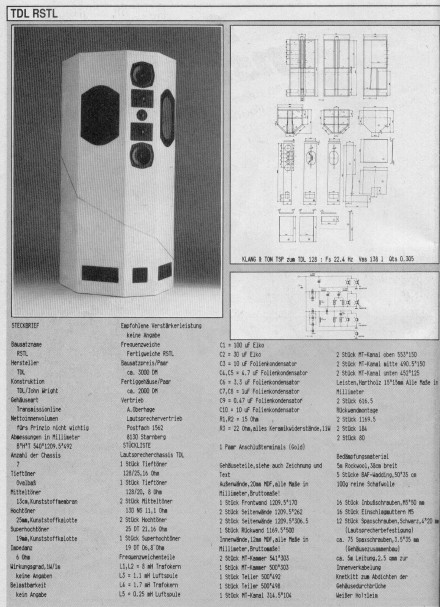

The original RSTL design was published as a kit in the December 1987 and January 1988 issues of the German DIY audio magazine Klang + Ton. I’ve searched all over for the entire article, but so far I’ve only found a link to a photo of one page from this topic on a forum for classic KEF speakers:

http://www.hifiloudspeakers.info/speakertalk/viewtopic.php?p=6854

I’ve copied the picture below to make sure this priceless heirloom isn’t lost. I’ll remove it at the request of the original owner. As you can see though it really isn’t clear enough to make out much of the required information, though after pouring over it for some time, I have gleaned a great deal of information from it:

My German is not what it used to be – actually I don’t know German at all – so I sat down with Google Translate and came up with this translation of the text:

Fact Sheet

RSTL

ManufacturerTDL

ConstructionTDL/John Wright

Enclosure TypeTransmission Line

Net Internal VolumeNot important for TL

Dimensions in mmWxHxD 540x1209x492

Number of Drivers7

WooferOvalbaß (oval)

Midrange13cm, plastic cone

Tweeter25 mm, Plastic dome

Super tweeter19 mm, Plastic dome

Impedance6 Ω

Efficiency, 1W/1mNot available

(Power) RatingNot specified

Recommended amplifier powerNot specified

CrossoverFinished crossover RSTL

Kit price/pairAbout 3000 DM

SalesA. Oberage

Lautsprechervertrieb

Postfach 1562

8130 Starnberg

Bill of Materials

Loudspeaker Drivers TDL- 1 woofer 128/25, 16 Ohm

- 1 woofer 128/20, 8 Ohm

- 2 mids 130 NS, 11.1 Ohm

- 2 tweeters 25 DT, 16 Ohm

- 1 super tweeter 19 DT 06, 8 Ohm

- L1, L2 = 8 mH Iron core

- L3 = 1.1 mH Air core

- L4 = 1.7 mH Iron core

- L5 = 0.25 mH Iron core

- C1 = 100 μF Electrolytic

- C2 = 30 μF Electrolytic

- C3 = 10 μF Film

- C4, C5 = 4.7 μF Film

- C6 = 3.3 μF Film

- C7, C8 = 1 μF Film

- C9 = 0.47 μF Film

- C10 = 10 μF Film

- R1, R2 = 15 Ω

- R3 = 22 Ω, ceramic, 11W

Cabinet Parts

refer to drawing and text

Exterior walls, 20mm MDF, all dimensions in mm, gross

- 1 front wall 1209.5×170

- 2 side walls 1209.5×262

- 2 side walls 1209.5×306.5

- 1 back wall 1169.5×500

- 2 MT-Chamber 541×303

- 1 MT-Chamber 500×303

- 1 Divider 500×492

- 1 Divider 500×498

- 1 MT-Channel 314.5×104

- 2 MT-Channel above 553×150

- 2 MT-Channel center 490.5×150

- 2 MT-Channel below 452×125

- 2 616.5

- 2 1169.5

- 2 184

- 2 80

- 5m Rockwool 38cm wide

- 5 BAF-Wadding, 50×35 cm

- 100g pure lamb’s wool

- 16 Allen screws, M5x50mm

- 16 T-nuts, M5

- 12 Screws, black, 4x20mm

- 75 Screws, 3.5x35mm

- 5m wire, 2.5mm², for wiring

- Putty to seal the enclosure openings

- 1 pr gold binding posts