I just had to get a peak at what it was going to look like loaded up. Nice! Note also my wonderful assistant, whose support both in the shop and out is instrumental to the success of this project. 🙂

DIY Design

Baffling!

Progress has been slow in recent times as it has been too cold to hang out in the garage. Still, there has been progress, especially on fitting the internal baffling: Notice also that the final section of the midrange line … Continue reading

Progress

An Elephant in the Room

Until now I’ve ignored one of the biggest cabinet problems – the Tang Band woofers are much deeper than TDL/Elac drivers used in the RSTL. How much deeper? Deep enough that I have to cut holes in the vertical dividers between the woofer and midrange sections to allow the woofer magnets room. Of course the woofer and midrange sections should not be open to one another, so I’ll need to build some sort of “cup” to cover over the hole from the midrange side. I didn’t design the hole size via a CAD system, but rather determined it empirically by cutting, trying to seat the woofer and repeat until it fit. I’m confident now I can make it work, but it certainly doesn’t appear in the original plans!

Resurrected

The good news is that I got a chance over the holiday weekend to cut and bevel (but not route) a new woofer panel and to cut and route (except for the TL terminus) the center section. With a number of “L” brackets, pieces are now held in place nice and tight. While it looks like a step backward from 2 months ago, overall it is actually progress. Really. 🙂

Broken!

The astute reader will notice I haven’t posted for the better part of two months. There are a few reasons for this. The first is that I’ve started a new job that takes much more of my time than my old job (60+ hours vs. 40 hours). I love my job at @Pay, but it seriously cuts back on my free time. Secondly, I suffered a series of setbacks in the form of broken pieces (and hence spirits). Both the woofer panels and M-T-ST-T-M panel get quite thin where the driver countersink diameter is the widest. If such a piece falls over flat against a cement garage floor, it can split right in two, taking hours of cutting, routing and so on with it.

I cut the panel shown slightly too narrow, exasperating the problem. A similar fate befell (ha!) a woofer section, it also breaking in two when it happened to fall over. Once supported by the rest of the cabinet structure, this won’t be a problem, but as free-standing structures they are fragile! I am going to reduce the depth of the countersink on the woofers to increase the strength of the panels.

Prototype shell!

I went to a one-day workshop on finishing techniques for wood a few months back. If I take nothing else away, it was worth it for this one thing – the strong advice to always make test samples first. This seemed like just too much work in this case, but finally I decided to go ahead. While there is much more to do, I finally completed an outer shell this past weekend:

A prototype for the outer shell for the RSTLM. It’s constructed from leftover pieces from my previous speaker project.

While I have a lot more work to do, I’ve already learned so much from the process I’m sold on the advice. Also, it is interesting to finally have a concrete view of the size of these. Until I saw it for real, I didn’t really know what they’d be like.

Go deep!

In my previous post, I mentioned a discussion about this project on the diyAudio site. One comment referenced an analysis by Martin J. King (http://www.quarter-wave.com/), widely regarded to have the best transmission line modeling software available. He stated that Dr. King had found “Dalines” (what G. L. Augspurger calls “Pipe with Coupling Chamber” ?) inferior to designs. I did find this reference on diyAudio that supports his statement.

Without further ado, here is my model of the Tang Band W8Q-1071F in a RSTL line. Could there be something better? Maybe. Does this strike me as a configuration that will have deep bass? Yes. Am I worried about the dip at 100Hz? Not really – right now I expect I’ll have an active crossover at or below 100Hz, so I’m not at all concerned. Should I go full passive, I’ll have to review my stuffing plans.

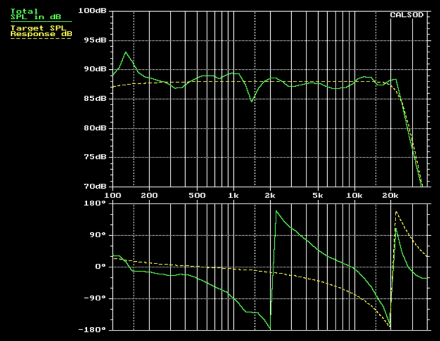

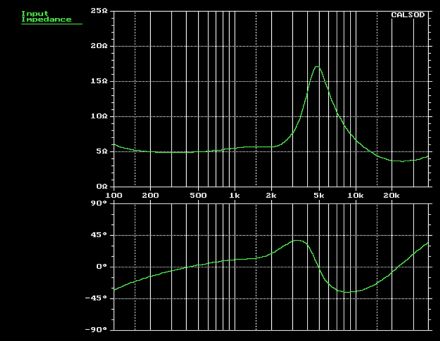

Proof of concept crossover complete

My goal was not to make a proper crossover, but rather to convince myself a crossover existed that would reasonably blend the upper three drivers (I’ve already decided it will be at least bi-amped) and have an acceptable impedance curve. I’ve been worried about the latter given that most drivers these days are 4 ohm and it is almost impossible to find any drivers over 8 ohms. Here is what I ended up with – a 4th order LR @ 2.2kHz and the super tweeter coming in at about 13kHz, 1st order.

The frequency response is quite acceptable, with the only major glitch being the notch at about 1.4kHz. That is in the woofer response and not a crossover anomaly. I’d have to look at a lower crossover point and/or a gentler slope to allow the tweeters to help fill that in. We’ll see. The impedance stays above 5 ohms until about 13kHz, so it shouldn’t be a difficult a load.

So I’d say mission accomplished.

The prototype drivers are here!

Since my second article back in February, I’ve done some re-thinking on drivers. I got a sample of the Vifa, but it my mind it was just too small. And too expensive for what it was. After finding and pouring over plans, I concluded that I could move to a 5″ class driver. After hours studying the Zaph Audio 5.5″ Driver Comparison page along with countless other resources, I decided try the SB Acoustics SB15NRXC30-8-UC for my prototype. For about $55, the distortion measurements are very close to the $200-$300 drivers he surveyed. On paper, it looks like the best 5″ value around. We’ll see how it sounds.

For the tweeter, I’ve had two ideas. One is to abandon the Tweeter-Super Tweeter-Tweeter arrangement completely and use a single tweeter with exceptional off-axis response instead. That is the reason Wright really went to the T-ST-T arrangement from what I can tell, to get good off-axis (the way the speaker was intended to be used) high frequency extension, not to extend on-axis response to 35K. The tweeter capable of crossing over at around 2K and yet having flat response at 20K @ 30 degrees off axis? Why the Seas SEAS 27TBCD/GB-DXT of course. The published data sheet shows the response 30 degrees off axis is only 1-2 dB down from the on-axis response. Wow!

This would be a major break with tradition though, which is disturbing to me. The center column then becomes a “regular” M-T-M. I wonder if Wright were alive today though if he would not do the same thing.

To take a more traditional approach, I’ve decided to change from the Scanspeak D2608/9130 that I had originally had my eye on to the SB Acoustics SB29RDCN-C000-4. This will allow me to keep the original driver spacing. I’d originally shied away from it due to the 4 ohm impedance, but with 94 dB sensitivity, I’ll have all sorts of room to manipulate the impedance in the treble. The M-T-ST-T-M configuration (I’m still using the NE19VTC-04 for the supertweeter) will look something like the picture to the left.